Range of Machines

An optimized process

Our machines provide an optimized process and BAR BREAK, in three steps:

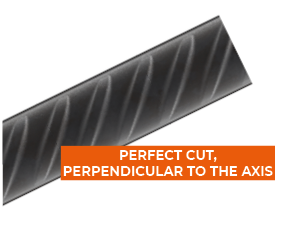

1 - Cutting process: A clean cut, perfectly perpendicular to the axis and without tabs.

2 - Cold forging process: Thanks to the synchronised action of two vices, the end section of the bar will be increased for a better resistance.

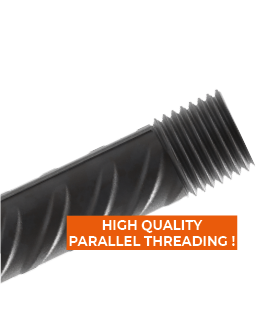

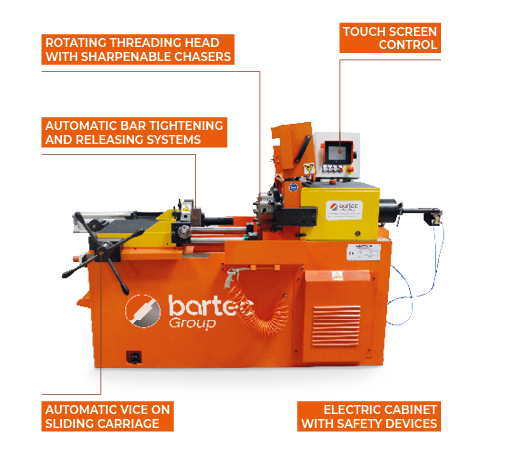

3 - Threading process: The cold forged part of the bar is being threaded, thanks to a threading head, optimized through an efficient exploitation, with among others, a touch screen control.