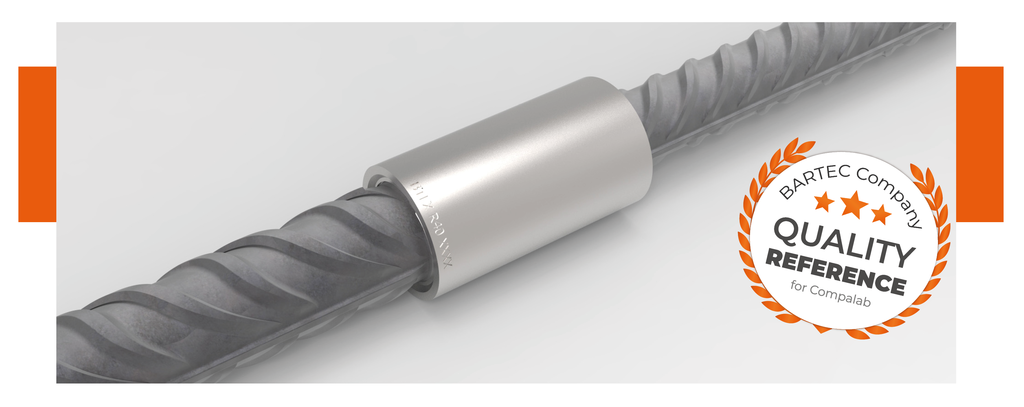

BARTEC becomes a reference gauge for Compalab !

Sometimes, a laboratory may execute a test twice and have different results. In that case, they can call out a Interlaboratory Comparator which will be able to identify error factors and attest the accuracy of their test results. For one of its operations, the ILC center Compalab, proposed to BARTEC Group to become a rebar splices reference caliber.

What is an Interlaboratory Comparison (ILC) ?

An ILC is an evaluation organized by a specialized institute for laboratories. It is used to measure the accuracy of their test results. Indeed, some laboratories realize tests whose results might be uncertain: differences can be observed because of imprecise measurements, uncontrolled methods, vagueness, etc.

The ILC results include the assessment of the bias and of the scatter of test results, a qualitative assessment of the uncertainties and a comparison of results obtained by using different test methods.

How does an Interlaboratory Comparison work?

The sampling:

For relevant results, samples need to be as identical as possible to the one tested by the certification center. The preparation and the verification are taken into consideration when the samples are tested.

The preparation:

This step is to reduce the uncertainty of every measurement to the minimum: a method of preparation, an identical environment for example. Some standards describe the procedure to follow according to the analyses that have to be done. The preparation can have a big influence on test results.

The analysis:

Analyses can be on:

- Chemical analysis (alloy steel, stainless steel, copper alloy…)

- Physical tests (resistance of stainless steel, thickness of galvanization…)

- Tests on liquid paints or organic coatings (thickness, shine, stripping ...)

- Coating age-resistance tests

- Mechanical tests (shock, hardness, tensile, fatigue)

- Tests on steels for reinforced concrete (tensile, geometry, linear mass ...)

Becoming a rebar splicing reference gauge for Compalab: A proof of reliability and consistency!

A consistent and homogeneous sample:

With BARTEC Group, we guarantee to deliver consistent samples. We conceive and create couplers ourselves, we define the thread fabrication process, done with our own machinery. It gives us the possibility to have a complete control on the whole production, with very precise results.

It should be noted that steel evolution and international standards brought us to file an international patent for our “Pi” range of products, already used in several countries.

A Quality Reference:

We have at heart the provision of reliable and good quality solutions. Our solutions have very good results on violent shock test (simulating the explosion of plane crash over a building for example), tensile, seismic and fatigue test (over 20 millions cycles!). During the production, we test 1 coupler for every 1000 created and we are certified ISO 9001, CARES, AFCAS, IGQ, DCL and GOST. All this means that we meet not only French standards, but also European and Worldwide standards.

To sum up:

Compalab is an assessment institute that performs Interlaboratory Comparisons. In order to correctly compare different results, they need reliable products, with consistent results on which to base their tests. If Compalab asked BARTEC Group to become a reference gauge for their laboratory, it is for the quality we offer and the consistency of our solutions, guaranteed by the complete control we have on our production line.

Read more on : www.compalab.org