To assemble reinforcements in reinforced concrete constructions, the covering system can be used: two reinforcing bars are superimposed over a length of 50 or 75 diameters, then embedded in the concrete in order to secure them. Depending on the situation, this solution may pose safety issues: in fact, in the event of a concrete fracture (in the case of an accidental overload or an earthquake, for example), the two reinforcements are separated, immediately destabilizing the structure with risks of ruin of the work.

Therefore, in order to make the assembly of the reinforcements as secure as possible (while saving steel), reinforcing link solutions have been created. The most common of these are BARTEC rebar links patented in 1988 by the eponymous company, then "Pi Range" rebar links patented in 2013 under the LINXION brand. They allow the load to be transferred from one bar to another, without depending on the adhesion or integrity of the concrete. The coupler connects the two bars, ensuring optimal structural continuity in its performance and reliability.

BARTEC Company has been specializing for more than 30 years in parallel threading with upset, a know-how from which its new LINXION subsidiaries have benefited. This technique offers:

- Flexibility of use, allowing optimal productivity to be achieved

- Guaranteed safety, thanks to 100% Bar Break

- Simple and safe control for repeatable quality on site

The BARTEC / LINXION parallel thread: a coupler for all types of connections

BARTEC & LINXION offer complete ranges of connections to meet all issues (standard, fatigue, stainless steel, etc.). The fact of using a parallel thread allows one and the same coupler to correspond to several possible combinations! One and the same coupler can be used regardless of the desired linkage: standard, position, adjustable spacing or lock nut, unlike taper thread or crimped couplers, where a special coupler will have to be used if the second bar cannot not be turned.

BARTEC Company's equipment has been designed to achieve maximum daily productivity. All bars are prepared in the chain, in sequence: the speed of the cutting, cold upsetting and then threading processes guarantees excellent productivity.

BARTEC rebar connection solutions: Quality & safety

All our couplers are made using CNC machines from quality cold drawn steel and according to a European Quality Management System (QMS). We follow strict and standardized control procedures (1 coupler tested every 1000 made).

Our links reduce bar concentration, improve structural integrity during all phases of construction, and provide better resistance against fatigue and earthquakes. Their installation is simple, quick and safe and facilitates visual inspection, made possible by the parallel thread.

In short: a simple, fast and secure solution!

For more than 30 years, BARTEC Company and the new LINXION subsidiaries have been convinced by parallel threading with cold discharge.

Flexibility, productivity, safety and quality: BARTEC & LINXION rebar connection solutions ensure:

- BAR BREAK performance, whatever the application or project,

- optimal security

- and ease of installation and control on construction sites

Whether in terms of fatigue, sliding, traction, earthquake ... BARTEC & LINXION rebar link solutions meet all issues and all international standards.

This is what makes parallel threading the most widely used system in the world!

Find our article on parallel threading below.

BARTEC COMPANY was awarded a rating of "STRONG" in a new analysis of the 159 largest companies in the French concrete reinforcement market. This is the highest honor Plimsoll bestows on companies.

Plimsoll is the leading publisher of industry studies and company reviews. More than 30,000 consultants, managers and directors trust PLIMSOLL for their sector studies in order to assess their market and their competition.

The Plimsoll study provides a standardized model that instantly shows the reader, financially trained or not, the overall well-being of any business. Based on extensive research aimed at identifying the most responsive financial ratios, the Plimsoll model instantly reveals the key elements of the commercial health of any business.

The Plimsoll Concrete Reinforcement Study (June 2020) individually assesses the 159 largest companies using the Plimsoll model. This proven, easy-to-read template highlights the latest performance of each business and separates struggling from successful ones.

The report instantly shows the strengths and weaknesses companies may have and the trend of the past 4 years. As a result of this analysis, a rating is assigned "STRONG, GOOD, MEDIUM, CONCERN or DANGER." These ratings reveal what is behind the performance of companies in the market.

Thanks to its connected machines and the use of videoconferences, BARTEC Company has succeeded in assisting its customers, even during this difficult period, in order to act remotely on working sites, to carry out analyzes and even remote start-ups. All these measures together with the good cohesion and goodwill of its employees, without which nothing would have been possible, have reduced the economic impact on the turnover of BARTEC Company.

This STRONG rating proves that Bartec Company has been able to anticipate, thanks to the research and development of new means to optimize production even more, to train always better and more efficiently, and thus allowing us to face this health crisis.

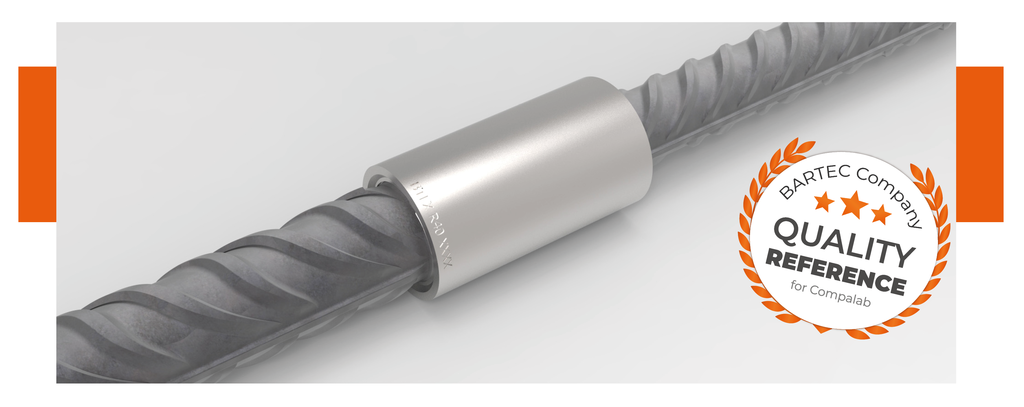

Sometimes, a laboratory may execute a test twice and have different results. In that case, they can call out a Interlaboratory Comparator which will be able to identify error factors and attest the accuracy of their test results. For one of its operations, the ILC center Compalab, proposed to BARTEC Group to become a rebar splices reference caliber.

What is an Interlaboratory Comparison (ILC) ?

An ILC is an evaluation organized by a specialized institute for laboratories. It is used to measure the accuracy of their test results. Indeed, some laboratories realize tests whose results might be uncertain: differences can be observed because of imprecise measurements, uncontrolled methods, vagueness, etc.

The ILC results include the assessment of the bias and of the scatter of test results, a qualitative assessment of the uncertainties and a comparison of results obtained by using different test methods.

How does an Interlaboratory Comparison work?

The sampling:

For relevant results, samples need to be as identical as possible to the one tested by the certification center. The preparation and the verification are taken into consideration when the samples are tested.

The preparation:

This step is to reduce the uncertainty of every measurement to the minimum: a method of preparation, an identical environment for example. Some standards describe the procedure to follow according to the analyses that have to be done. The preparation can have a big influence on test results.

The analysis:

Analyses can be on:

- Chemical analysis (alloy steel, stainless steel, copper alloy…)

- Physical tests (resistance of stainless steel, thickness of galvanization…)

- Tests on liquid paints or organic coatings (thickness, shine, stripping ...)

- Coating age-resistance tests

- Mechanical tests (shock, hardness, tensile, fatigue)

- Tests on steels for reinforced concrete (tensile, geometry, linear mass ...)

Becoming a rebar splicing reference gauge for Compalab: A proof of reliability and consistency!

A consistent and homogeneous sample:

With BARTEC Group, we guarantee to deliver consistent samples. We conceive and create couplers ourselves, we define the thread fabrication process, done with our own machinery. It gives us the possibility to have a complete control on the whole production, with very precise results.

It should be noted that steel evolution and international standards brought us to file an international patent for our “Pi” range of products, already used in several countries.

A Quality Reference:

We have at heart the provision of reliable and good quality solutions. Our solutions have very good results on violent shock test (simulating the explosion of plane crash over a building for example), tensile, seismic and fatigue test (over 20 millions cycles!). During the production, we test 1 coupler for every 1000 created and we are certified ISO 9001, CARES, AFCAS, IGQ, DCL and GOST. All this means that we meet not only French standards, but also European and Worldwide standards.

To sum up:

Compalab is an assessment institute that performs Interlaboratory Comparisons. In order to correctly compare different results, they need reliable products, with consistent results on which to base their tests. If Compalab asked BARTEC Group to become a reference gauge for their laboratory, it is for the quality we offer and the consistency of our solutions, guaranteed by the complete control we have on our production line.

Read more on : www.compalab.org

In order to limit the risk of financial loss, artisans rely on the accompanying measures announced by the government. They also hope for measures intended for employees.

For several weeks, France has been facing the spread of an epidemic. The building activity collapsed by 75% in March, leading the French President to ask everyone to ensure the continuation of its activity under satisfactory health safety conditions.

It is therefore necessary to strive for continuity of their activity, to avoid a complete shutdown of the construction sites.

The Government is aware of the difficulties for the construction industry when it comes to implementing barrier measures, but also in their ability to obtain materials and equipment and to mobilize the necessary personnel. This has led to the slowdown, even shutdown, of many construction sites in the country since the start of this epidemic.

Both representatives of construction companies and the Government agreed on several principles to strengthen the continuity of activity in the sector and the continuation of construction sites.

Construction sites in front of COVID-19

Containment measures have led to site temporary shutdowns. The government and the professional federations are working on a protocol to allow their restart.

Faced with the stoppage of construction sites, the French construction and public works prevention organization (OPPBTP) has set up a guide of good practices, validated by the Government, to allow the continuity of work. It lays down urgent and specific measures to be observed during the Covid-19 epidemic, to ensure satisfactory sanitary conditions for construction workers.

If a company fails to comply with the recommendations on its construction site, then, it will be required to stop operating on the latter. Companies that cannot adapt their operations or implement the set recommendations may resort to partial unemployment.

Workers’ health and safety is the main concern. Vigilance must be maintained on standard site risks. These general instructions concern the observance of barrier gestures, hygiene, site-access control and staff information, all of which must be considered as rules. Instructions aim to encourage home-office, to restrict on site staff presence as well as staff travelling, business intervention and site developments.

Some measures to be aware of on construction sites:

- basic hygiene rules display: wash your hands regularly, do not shake hands, respect social distances

- Reinforce the premises’ cleaning and intensify its frequency: lockers, refectories, toilets and site offices, you may decontaminate premises if necessary

- In order to avoid having to many workers at the same time on site, site arrival times, meals and site slots between on site operating companies, can be shifted.

- Make sure that workers’ concentration is not too important in confined spaces, with regards to intervention planning

- Ban site meetings and communicate by email, videoconferences.

Bartec Group in front of COVID-19

In order to cope with this epidemic, our company has known how to be reactive. It has placed the safety and health of its employees first.

Philippe Huet, Bartec Group CEO, tells us more about the various measures taken for the sake of Groups’ activity and employees.

"We have just gone through an exceptional crisis … the kind of crisis like the world has not seen in a long time.”

No one could have foreseen such an unpredictable, almost unimaginable crisis, yet BARTEC Group was ready to face this unprecedented crisis;

Indeed, BARTEC Group:

- Had strengthened its capital base in 2019 to cope with face such a situation and even more to be able to continue and maintain its development, initiated years ago,

- Is equipped with a high-performing connected computer network allowing all its employees to work on the general server no matter where in the world they may be located,

Its connected machines and the use of videoconference tools have enabled BARTEC Group to assist customers, even during this difficult period, and to act remotely on construction sites, carrying out remote analyses, and even remote start-ups.

All these measures, added to the good will and to the involvement of company staff, without whom nothing would have been possible, have made it possible to reduce the economic impact on BARTEC Groups’ turnover.

Used to continuous improvement process BARTEC Group will develop in the coming years for all of its subsidiaries abroad the intensive use of remote communication, preventive maintenance, acquisition of statistical data to further optimize production, and to improve.

In spite of the looming major economic crisis, management and shareholders have taken employee health and safety very seriously:

- Even before the official announcement of the general confinement, the employees were invited to stay at their homes as of March 16th.

- The physical distancing measures and the barrier gestures had already been implemented several days before the official obligations,

- Wages have been a 100% maintained for all employees, short-time workers included

- Punctual interventions which could not be done by telework, have been realized under strict sanitary conditions, priority being clearly given to safety before execution efficiency.

Chinese have an expression "Wei-ji meaning CRISIS. The first character means "Danger" and the second one "opportunity".

Boosting its Chinese subsidiary during this period, by hiring new engineers and by initiating a large-scale partnership on this market, representing 20% of the worlds’ market share

BARTEC Group has fully complied with this Chinese expression. At the date of today, this partnership in China is about to be signed and will allow BARTEC Group to confirm its global business take off “.

Let’s hope that Construction industry will not suffer a major economic impact

In fact, it appears that more than half of the construction sites have reopened by now.